Classifications of Biological Safety Cabinets

In the realm of laboratory safety, biological safety cabinets (BSCs) play a pivotal role in protecting researchers, technicians, and the environment from hazardous biological materials. These cabinets are designed to provide a safe working environment by controlling and containing contaminants. However, within the realm of BSCs, there are different classifications and types, each serving specific purposes. In this comprehensive guide, we delve into the classifications of biological safety cabinets, highlighting the distinctions between laminar flow hoods and BSL cabinets. Additionally, we’ll provide a lab maintenance checklist to ensure the proper functioning and safety of these essential laboratory instruments.

Understanding Biological Safety Cabinets:

Biological safety cabinets are essential equipment in laboratories working with hazardous biological agents such as bacteria, viruses, and toxins. They provide a contained environment where work can be performed safely. These cabinets operate based on the principles of airflow control to prevent contamination of the work area, personnel, and the surrounding environment.

Classification of Biological Safety Cabinets:

Biological safety cabinets are classified into different types based on their design, airflow pattern, and level of protection they offer. The primary classifications include Class I, Class II, and Class III cabinets.

- Class I Biological Safety Cabinets:

- Class I BSCs are the simplest form of biological safety cabinets.

- They provide personnel and environmental protection but do not protect the product.

- Air is drawn from the lab and passed through a HEPA filter before being exhausted into the environment.

- These cabinets are suitable for working with low to moderate risk biological agents.

- Class II Biological Safety Cabinets:

- Class II BSCs are the most commonly used cabinets in laboratories worldwide.

- They provide both personnel and environmental protection, as well as product protection.

- Airflow in Class II BSCs is recirculated through a HEPA filter to provide a sterile work environment.

- Class II cabinets are further divided into four types: Type A1, Type A2, Type B1, and Type B2, each with specific airflow patterns and applications.

- Class III Biological Safety Cabinets:

- Class III BSCs are highly specialized cabinets designed for maximum containment of hazardous materials.

- They are completely enclosed and provide maximum protection to personnel, the environment, and the product.

- Operations within Class III cabinets are conducted via glove ports, and all materials are sterilized before removal from the cabinet.

Laminar Flow Hoods vs. BSL Cabinets:

Laminar Flow Hoods:

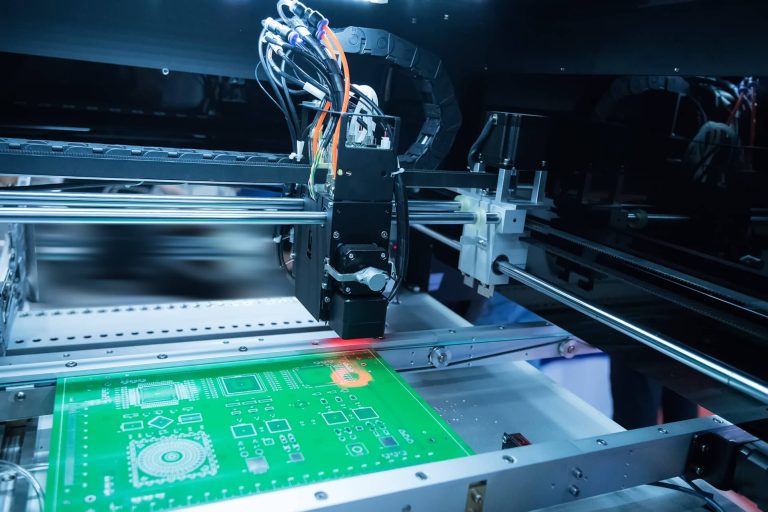

Laminar flow hoods, also known as laminar flow cabinets, are designed to provide a sterile work environment by directing filtered air in a unidirectional flow over the work surface. These hoods are commonly used in applications requiring a clean environment, such as tissue culture, microbiology, and electronics assembly.

Key Characteristics:

- Laminar flow hoods provide product protection but offer minimal protection to personnel and the environment.

- Airflow in laminar flow hoods is unidirectional, moving parallel to the work surface.

- These hoods are not suitable for working with hazardous biological agents unless additional containment measures are implemented.

BSL Cabinets:

BSL (Biosafety Level) cabinets, on the other hand, are specifically designed to handle hazardous biological materials safely. They come in various classes, as discussed earlier, providing different levels of protection depending on the risk associated with the biological agents being handled.

Key Characteristics:

- BSL cabinets provide personnel, environmental, and product protection, making them suitable for working with a wide range of biological agents.

- These cabinets feature HEPA filters to ensure the containment of airborne contaminants.

- BSL cabinets are essential for laboratories working with pathogens requiring containment, such as bacteria, viruses, and toxins.

Lab Maintenance Checklist for Biological Safety Cabinets:

Regular maintenance is crucial to ensure the optimal performance and safety of biological safety cabinets. Here’s a comprehensive checklist for maintaining BSCs in your laboratory:

- Daily Maintenance:

- Wipe down all surfaces inside and outside the cabinet with an appropriate disinfectant.

- Check airflow indicators to ensure proper airflow within the cabinet.

- Inspect HEPA filters for any signs of damage or contamination.

- Weekly Maintenance:

- Clean and decontaminate the work surface and any equipment inside the cabinet.

- Inspect gloves for signs of wear and tear, and replace if necessary.

- Test the alarm system and UV light (if equipped) to ensure proper functioning.

- Monthly Maintenance:

- Perform a thorough inspection of all cabinet components, including seals, gaskets, and airflow grills.

- Test and calibrate airflow velocity and alarm systems according to manufacturer guidelines.

- Check and record the pressure drop across the HEPA filters.

- Annual Maintenance:

- Schedule a professional certification and recertification of the BSC by a qualified technician.

- Replace HEPA filters as recommended by the manufacturer.

- Conduct a thorough inspection of the cabinet’s electrical components and connections.

Conclusion:

Biological safety cabinets are essential equipment in laboratories where work with hazardous biological materials is conducted. Understanding the different classifications of BSCs, including laminar flow hoods vs BSL cabinets, is crucial for ensuring the safety of personnel, the environment, and the integrity of the research being conducted. By adhering to a comprehensive lab maintenance checklist, laboratories can ensure the optimal performance and longevity of their biological safety cabinets, thereby maintaining a safe and productive working environment.